Fully Biological Wastewater Treatment: The Fluidized Bed Process Advantage

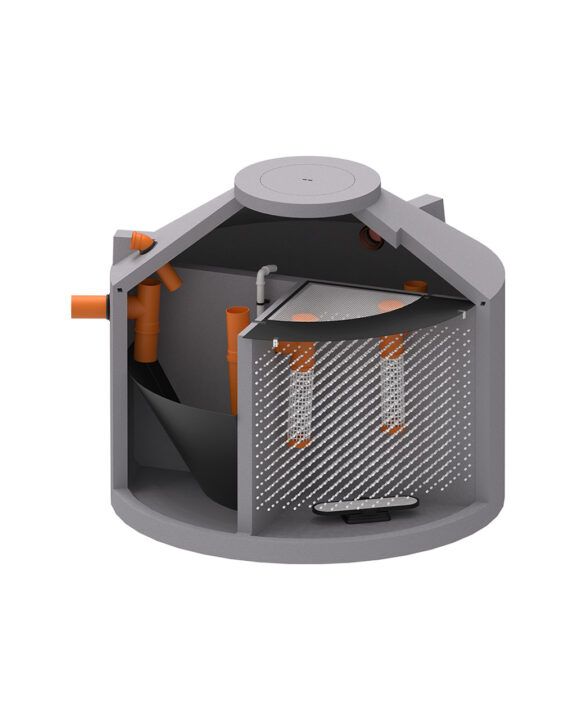

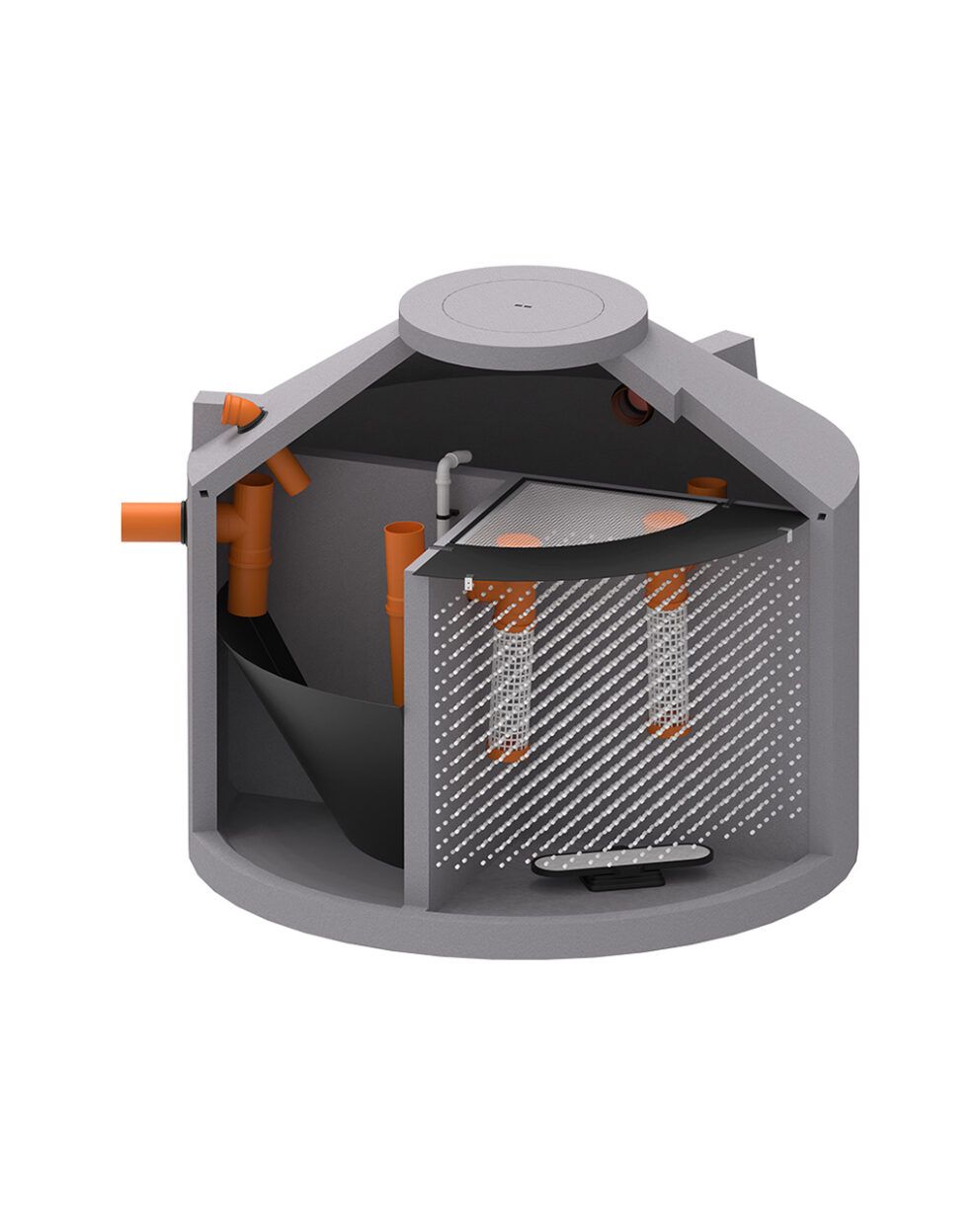

AQUATO® 3K-FLOW

At AQUATO®, we introduce the 3K-FLOW: a pioneering small WWTP that delivers excellent purification performance using the advanced fluidized bed process. It is specifically designed for environments with strong inflow fluctuations and permanent low-load operation. The 3K-FLOW is energy-efficient, high-performing, and contains no mechanical equipment inside the tank. The system is resistant to aging from domestic wastewater and ensures maximum operational reliability. Ideal for new construction or retrofitting existing three-chamber systems.

-

•

No In-Tank Mechanical Equipment

-

•

Energy-Efficient and High-Performing

-

•

Reliable under Low-Load Conditions

-

•

Retrofit Capability for Existing Systems

-

•

Wear-Free Tank Components

-

•

Optimal Purification Performance Starting at 1 Person

Variant

AQUATO® 3K-FLOW

How Does the Fluidized Bed Process Work?

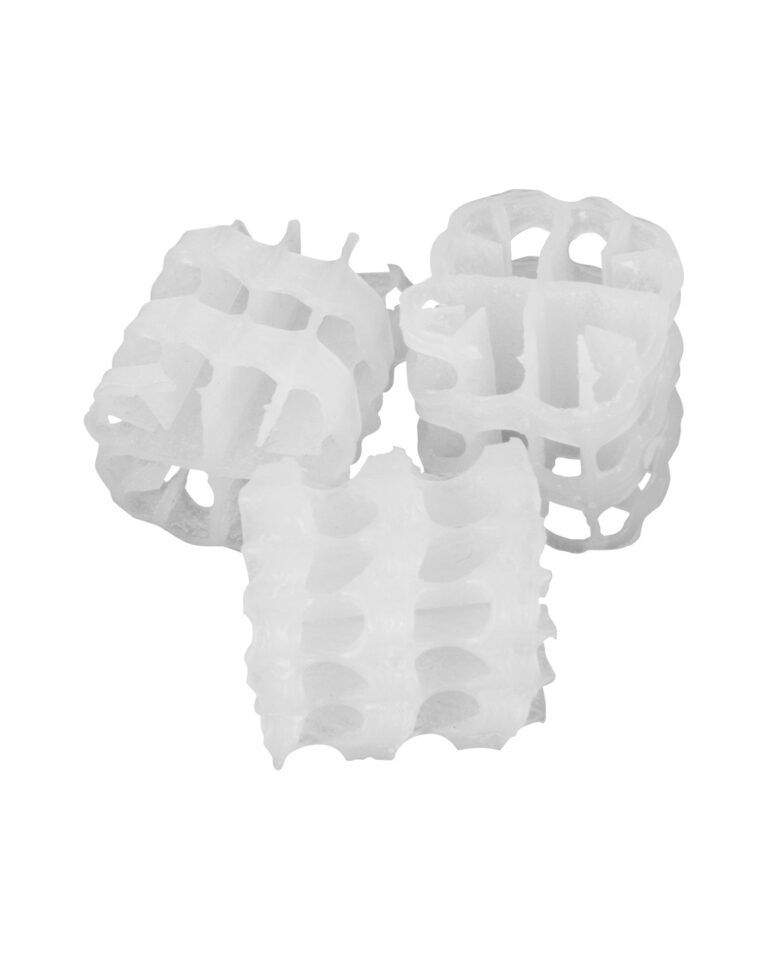

The Fluidized Bed Process (WBBR) is a biological wastewater treatment method that utilizes freely moving plastic carriers. Microorganisms (biofilm) settle on these carrier media to purify the wastewater. The carriers are kept in constant motion by aeration, ensuring maximum purification performance.

This process is characterized by its high treatment efficiency, compact design, and the ability to maintain stable operating conditions even with fluctuating loads.

Sampling takes place during the final clarification phase.

How Does the Fluidized Bed Process Work?

The Fluidized Bed Process (WBBR) is a biological wastewater treatment method that utilizes freely moving plastic carriers. Microorganisms (biofilm) settle on these carrier media to purify the wastewater. The carriers are kept in constant motion by aeration, ensuring maximum purification performance.

This process is characterized by its high treatment efficiency, compact design, and the ability to maintain stable operating conditions even with fluctuating loads.

Sampling takes place during the final clarification phase.

AQUATO® 3K-FLOW

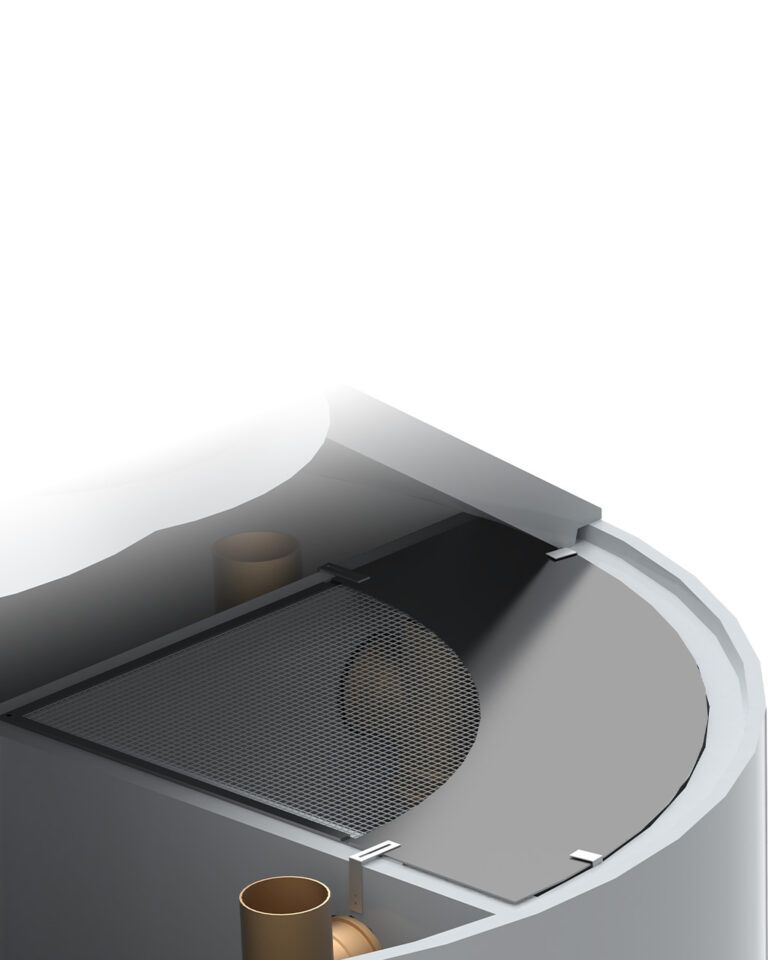

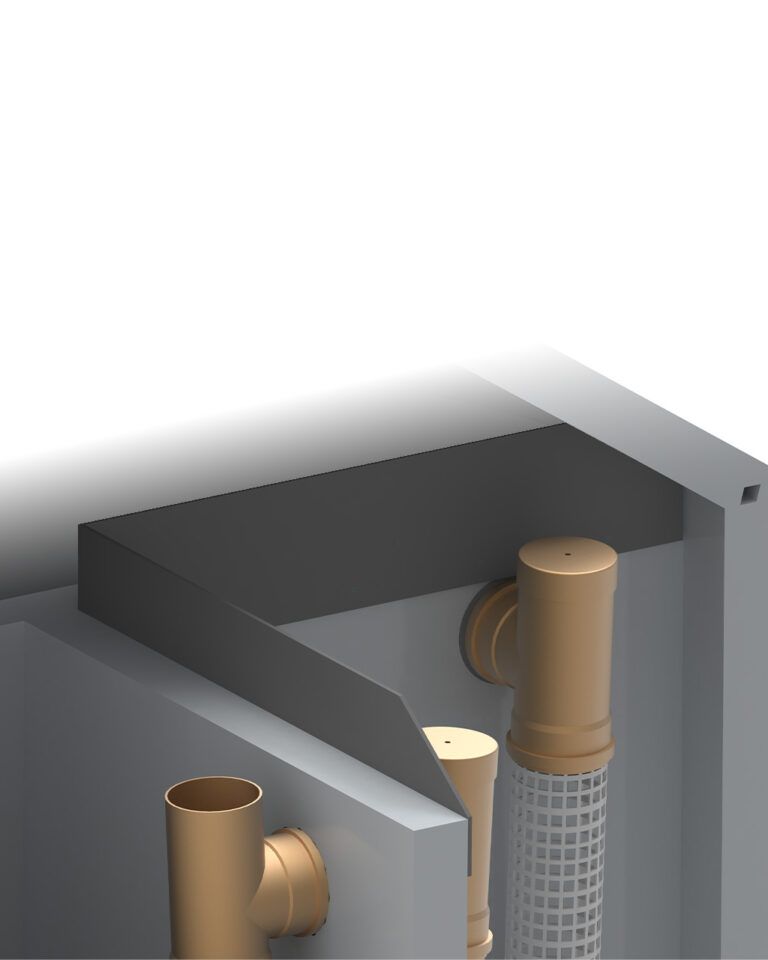

Scope of Delivery

Every AQUATO® system is delivered complete with all necessary components for smooth and reliable operation. The technology, including the control unit and compressor, is conveniently located in a dry, easily accessible area outside the tank. A comprehensive solution for fully biological wastewater purification.

Siphon

Plate Aerator

Alternative aerator types available.

Compressor

Depending on the number of PE.

K-PILOT 2.4

State-of-the-art Control Technology with External Rotary Valve

Fixed Film Media

Reactor Cover

Partition Wall Elevation

Tanks

Outdoor Columns & Installation Options

Outdoor Column 6.1T

Outdoor Column X7

Smart Tools and Extensions: Digital Intelligence for Your Wastewater System

Expand the functionality of your AQUATO® wastewater treatment plant systems with our intelligent tools and modules. We provide customized solutions for advanced control, comprehensive monitoring, and optimized efficiency.

Control

Smart Extensions

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Control

K-PILOT 2.4

Newly developed control for maximum flexibility and long service life.

Wi-Fi Direct

Convenient wireless access and wireless updates.

Smart Extensions

Makes your K-PILOT 2.4 IoT-enabled for remote access and cost savings.

Additional Treatment Stages

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

H-Modul

Chemical-free UV disinfection for maximum hygiene and water reuse.

CL-Modul

Cost-effective chlorine disinfection to meet specific requirements.

P-Modul

Effective phosphorus elimination to protect sensitive water bodies.

C-Modul

Stable nitrogen removal even with fluctuating plant loads.

FAQs

You have questions? We have answers!

What is special about the fluidized bed process of the AQUATO® 3K-FLOW?

The Fluidized Bed Process utilizes special carrier media where cleansing microorganisms settle to form a stable biofilm. This ensures excellent purification performance, even when facing strong inflow fluctuations and sustained low-load operation.

Are there electrical components installed in the water with the AQUATO® 3K-FLOW?

No, the AQUATO® 3K-FLOW system operates without any energized or mechanically stressed components inside the tank or wastewater area. This maximizes operational reliability and simplifies maintenance.

Can the AQUATO® 3K-FLOW be integrated into existing tanks?

Yes, the 3K-FLOW is perfectly suited for retrofitting. It can be installed in existing concrete tanks that comply with DIN 4261 and feature a three-chamber layout. Custom adaptation to accommodate older tank sizes is also possible.

Ready to Assist.

Let our expertise guide you. Contact us for a personalized consultation and receive detailed information about our systems and available extensions.

Provide your email – we’ll contact you soon.